Jay Fisher - Fine Custom Knives

New to the website? Start Here

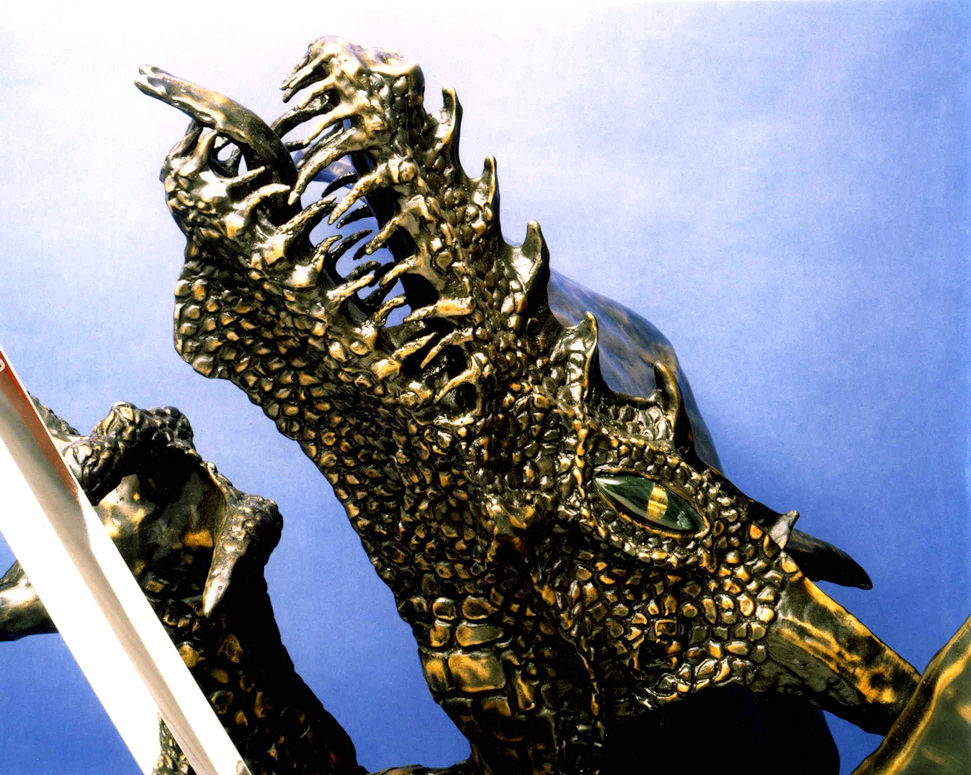

"Kotori"

There are cultures where edged weapons and tools are held in high regard, even cherished. I remember hearing about a modern Pueblo people who have a stone axe resting in a prominent spot in their place of worship. This is because it hearkens to an earlier time when they used stone axes and they honor their ancestors with the display, even though today they use chain saws and hydraulic wood splitters to process timber.

I try to honor the history of edged weapons and tools with my own work. I often look to the past for inspiration and ideas and for design continuity and guidance. I believe this honors the history of man's first and oldest tool and its place in our culture and modern times.

The knife, sword, tool, or weapon is the main focus of attention (as it should be), but because knives and edged weapons can be dangerous forms, we are usually conscious of their potential for injury, and often have them stored away, sheathed, and secured. High value can also mean that a fine custom or handmade knife is a substantial investment and should be protected.

High value investment grade works in knives, daggers, swords, and edged weapons and tools are also art. When the inspiration, design, execution, craftsmanship, and artistic effort is applied, knives become works of art and are deserving of a complete display. This display is a stand, case, or cohesive sculptural work that completes the piece.

When a knife transcends a simple sheath and requires a more elaborate and artistic method of display, the display stand or case is created. My display stands or cases must hold the knife at a flattering angle, must compliment yet not detract from the knife's artistic style, must complete the entire ensemble to become a solid and independent piece of art, commensurate with the quality of the knife.

Like most beginning makers, early on I started with display stands of deer antler attached to wooden bases. While that may be suitable for early works and for hunting knives where the antler is a point of appropriate interest, it was just the beginning. I quickly moved to stone components, metal fittings, hardwoods carved and finished, and complimentary arrangements. In my display cases I realized that fine joinery was appropriate, with fine woods, carving, milling, and variety that would compliment the knife and be heavy, substantial, and offer worthwhile and long-term protection, display, and value to my clients.

As development progressed, the block, stand, or case encompassed more specific functions and necessary materials. Read on!

Some of my stands and display cases incorporate both the knife and sheath, and some just the knife. My stand or case designs are one-of-a-kind and may range from simple to elaborate, utilitarian to fantasy, all complimenting the knife, dagger, sword, or weapon, and suited to the purpose of the piece. The stands or cases may represent the image of the knife, often echoing curves and stylistic accents on the knife or handle. Some incorporate the same materials that are used in the construction of the knife. Some are animate and recognizable, some are abstract or geometric.

They feature finely finished or polished pieces with accurate fittings and mounts solidly designed with stable bases or heavy and solid hangers. Sometimes, an etched or engraved (by machine or hand) nameplate identifies the piece, occasionally it details the components, and occasionally an illuminating poem follows to complete the artistic idea.

Though you'll see some beautiful stands and cases on this page, you'll notice that no two are alike. Occasionally, I get requests to copy my own stands for new knives. I don't do this, because it would devalue the existing stand that is in the hands of a client, and I'm committed to make each stand an individual artistic endeavor.

Blocks, stands and cases can add great value to the overall knife or knives. Unlikely to appear in any manufactured works and original to each maker or artist, stands, blocks, and cases become significant parts of each work of art. They may represent many hours, weeks, or even months of effort on the part of the artist. High value components like cast bronze, precious gemstone, and high detail engravings may be part of the knife art display. The creation and execution of the construction of these stands is the complete province of the maker, and speaks to his skills and practice in the field.

Making fine stands and cases is a challenging artistic skill in itself, matching the right woods, horn, bone, ivory, or gemstone to the knife, displaying the knife and complimenting it, adding to the piece rather than pulling the eye away from the knife. As the knives become more elaborate, so do my stands and cases, until it is impossible to separate the two and they are a total sculptural art piece.

Many people do not realize what goes in to a fine sculptural stand, case, block, or presentation device. Carving, shaping, finishing and mechanics are all parts of the knife sculptural experience. Welding, carving in wax, casting metals, fitting stone, and other necessary skills are employed in the creation of the idea. A great deal of hand work and finishing is applied to bring the potential out of the rough materials used in the custom stand, case, or block. All of this takes a great deal of time.

Fine chef's knives that will occupy a prominent space on the counter need custom blocks. Below you will see some fine blocks, stands, and cases I've made in hardwoods. These are multi-component, heavy, and substantial pieces made with hardwoods and gemstone, with plenty of mass for stable protection of the knives and owner. Some of them are accompanied by nested chopping bowls and spice blocks that match the curvature of the specialized blades. The taller blocks may have stone bases (granite) for stability.

When we had chef Tommy Badger Brown and his production crew (Ken Korpi, Matt Levinson, and Todd Westphal) visiting early in the spring of 2020, we discussed chef's knives and all of the uses, accessories, and necessities of the typical chef's knife. I use the singular word "knife" because a chef can only use one knife at a time. As the chef uses the knife, he (or she) picks it up, and puts it down many times during the preparation. Most people will just lay it on the counter or on the cutting board. They wouldn't put it in a block or holder, because it has not been washed. The knife can move, spin around, and present a razor-scalpel edge to the chef's hand, since it doesn't have a secure place to rest.

This issue is one of the reasons I first created the microfiber towel set that I include with my chef's knives. The towel gives a resting place for the knife, while in use, and another place for it to dry. Read more about the issue and the microfiber towels at this link.

Another issue is where to store the knife, particularly if the knife is singular and doesn't have a block or stand. Sometimes, the knife might need to be put in a drawer, and this would be dangerous to the hand reaching in, and brutal to its cutting edge and other stainless utensils. The fine knife is razor-scalpel sharp and needs to be respected. A dedicated slot in a drawer is precious and limited real estate in most kitchens.

This is how my wife and I came up with the idea for the "prise," (pronounced preeze or prize)The name comes from the French prise de fer, which is a movement used in fencing in which a fencer takes the opponent's blade into a line and holds it there in preparation to attack. The French word prise simply means taken.

The prise is a home for the knife, it is a rest for the knife, it is more than that, it is a trap for the knife that holds it "in a line" in preparation for the next "attack" of cutting and board work.

You might be tempted to call the prise a rest, like a spoon rest, merely a place to plop down a dirty utensil, but It is so, so much more. A spoon or utensil rest is a temporary fixture, remaining empty most of the time, and it can slide around. It is often in the way, and can be difficult to clean. A spoon rest is not specifically designed for an individual utensil, and it typically only elevates the dirty part from the countertop. A spoon rest is no place to store the utensil, it's not safe, it's not permanent, it's not long-lasting. It rarely fits the utensil, since it is not designed around the utensil.

It's entirely a new concept, one suited to just one individual knife, and molded around it. It's not a holder, block, stand, base, or rest.

The prise is so much more than any of those. I made the prise in food contact safe high density silicone rubber, and dyed it to match the ensemble. This is high strength material, with 800 psi tensile strength. It's resistant to 450°F (232°C) heat, and no food stuff sticks to it. It's flexible, yet stout and thick, and can be easily cleaned, rinsed, and even baked dry. It's also Food Contact Safe.

This is a wonderful material, and I create the mold and hand-cast the prise so that the silicone fits the specific knife. I've designed them with finger holes for easy removal, and the bottoms have a base that grips any countertop it sits on.

Gripping is important! The silicone prise is "grippy." Being of smooth silicone, nothing slides around on it. If the chef is working with his knife, and needs to set it down for a period, he doesn't need to worry about placing the knife precisely in the socket of the prise, just dropping the knife on the prise assures it will not move; it wont' even budge! The knife can sit atop the prise and still be sound and secure. The prise is an elevated safety zone for the knife during use, as well as safe storage and display before and after use.

Even though the silicon is grippy to the knife, the silicone will not bond to moisture, foodstuffs, or anything else, and usually a quick rinse is all that is required to clean it. Like any knife, board, or utensil, a brush-cleaning with soapy water is advisable when working with raw chicken and meats, but that's easy enough. You can even plop it in the dishwasher, but I don't think you would ever need to. The silicone prise dries almost instantly; water and liquids just bead up and flow off of it.

You might have noticed that the prise is designed to have the reverse side of the knife facing upwards. I did this because my chef is right-handed. When the prise is stored beside the board, the point is away from the chef and the cutting edge is also away from the chef's hand. If the prise is placed along the top edge of the board, the cutting edge is away from the right-handed person when they pick up the knife, the safest arrangement. Of course, I can make these for a left-handed person as well; the orientation will be reversed.

Storage issues are eliminated with the prise. since it's color-matched to the knife and ensemble, it looks great on the counter. Please look at the various and creative matching prise photos below. When the knife is not being used, it's nested down in the prise, and the cutting edge and point of the blade can't be touched. It won't fall out, it won't move, it's safe, and yet immediately available. The tough silicon will resist cutting since it flexes, and because of the grippiness, the prise will not slide or move on the counter; it clings to the counter. If there is a need to store the knife in a drawer, the prise is a dedicated, rectangular safe, a nested receptacle for the knife, assuring it does not move, and does not contact any other utensil.

The prise is dense. This means solid, and with some weight, so it's durable and won't move around. The prises shown in this section come in at almost two pounds; they are an inch thick and about a foot long. This is why you won't see a prise offered anywhere else; it's a massive, solid piece of high strength silicone. Yet, because of its size and softness, each prise easy to manipulate and clean.

The prise a perfect holder/rest/trap/storage device, and it's completely food contact safe. I'm certain I'll be making more of these, and I've cast my maker's mark into them with pride.

What about the board? A board to match the project would be a good idea, and here's my take on it: Many boards are large and unwieldy. They are thick and heavy, with heavy handles, heavy feet to elevate them, or they are plastic and slide around on the countertop. This may be fine for some of us guys with large, strong hands, but it can be difficult to move a board to wash it.

In the photos below, you'll also see a prise for the board. The idea here is that some boards can be heavy, but some people prefer a board that is easier to lift and handle and clean. And since boards are replaceable, there may not be a need for a super heavy thick board, but a lightweight replaceable board. This is my idea for the board prise.

Like the knife prise, the board prise is a thick, heavy, and strong piece of silicone rubber. It grips the countertop, and won't move. It also grips the board securely, so it won't move or slide around. The board is rigid and immovable when on the prise, and the thick prise elevates the board for easy removal of cut foodstuffs or moving them into containers, pans, or cooking ware. The board prise also has a lip around the edge to trap liquids. The design of raised silicone parts also allow ventilation and proper drying of both the board and the board prise.

Like the knife prise, it's Food Contact Safe, and it's washable and withstands 450°F. It's a tough silicone (this one has a 800 lb. tensile strength), and incredibly long lasting. It would be an easy think to replace the board or change the board out with another type or material while using the board prise over and over. The board is elevated by the design work inside and I customize it with my maker's mark, since I make them here in the studio, custom fit and dyed to the project.

One more thing: the silicone rubber prise for the board is a high temperature food contact safe material. This means that it can double as a pot rest or cooling pad, and may have many other applications. You could even bake on it! I designed it with a lip around it to retain fluids, yet it flexes easily. You might think that it would be difficult to clean with the floral design, but remember, this is silicone, and nothing sticks to it!

The prise is a fantastic addition to the fine custom knife that will be used by a professional chef. Beyond the microfiber towel, more secure than a block or stand, and creating a safe zone for the working knife in the kitchen, the prise is a prize! Custom dyed and hand-cast, the prise can match the project, knife, environment, or artistic idea. More to come!

Return to TopicsThe knives I make are incredibly wear-resistant. My T3 and T4 cryogenic process for high alloy, hypereutectoid martensitic stainless steel blades produce knife blades that only need to be sharpened occasionally. In the normal home kitchen this means once or twice a year. For the professional chef who uses his knife daily and on very tough, brutal cutting chores (think dried galangal root, acidic tomatoes and lemons, dried fruit, nuts, and seeds), he may need only one sharpening a month. But every single knife, no matter how wear-resistant, will, sooner or later, need sharpening.

In order to provide my clients with the tools for this, over the decades, I've recommended books and techniques, methods and descriptions, and knife care instructions. These are helpful, but I wondered if I could do more.

It's important to realize that standard sharpening stones—silicon carbide, aluminum oxide, ceramic, novaculite, Japanese stones, etc.—will not reliably sharpen these ultra-hard knives. Sure, they can be used, but it will literally take many hours to sharpen my cryogenically treated knives with the conventional sharpening tools often destroying the stones and hones themselves! What is required to do the job quickly and reliably is diamond abrasive.

Nothing is harder or more abrasive than a diamond sharpening "stone." These are not stones, per se, but a field of industrial grade diamond abrasive particles embedded in a nickel plating on a substrate that is usually steel or a very durable phenolic. Some of the best diamond stones are made today, and they are expensive, but much less costly than 10 years ago. DMT makes some great, professional diamond hones and this is what I use to produce sharp edges on my knives. Some of these stones are double-sided to allow a coarse removal of steel followed by a fine honing of the edge.

I've included small versions of double-sided diamond hones in my ultimate tactical knife kits for years. I also had to include a heavy, thick nylon stitched bag and pad with them. This is because diamond abrasive will absolutely ruin everything it touches. If placed on a counter, desk top, bench, table or other surface, the diamond will scar, tear, and rip the surface to shreds. Remember, the bottom of a double-sided diamond hone is extremely abrasive as well as the top. Also, the diamond stone/hone can slide around on the table or surface, making it unstable and unsafe to use for a sharpening. DMT and other companies know this, and often include a paper-thin sheet of silicone rubber or other soft plastic to help control this, but it's not enough.

This is why I started building the silicone prise for the stone. It's a thick (about 1/2") piece of hand-dyed, hand-cast molded food contact-safe silicone rubber, and it has a dedicated, perfectly-sized pocket to nest and embrace the sharpening stone. The silicone pad is laid on the surface, protecting it from the abrasive diamond particles. The stone is placed inside the pocket, pressed in, and then sharpening begins. The silicon flexes a tiny bit, but holds the diamond stone securely, and the stone can be flipped over for the final stages of sharpening. The silicone (and the diamond stone) can be washed with soap and water; they both quickly dry, and can be stored. In the photos below, I've made a special drawer to store the sharpening kit. Genius!

The prise is a fantastic addition to the fine custom knife that will be used by a professional chef. Beyond the microfiber towel, more secure than a block or stand, and creating a safe zone for the working knife in the kitchen, the prise is a prize! Custom dyed and hand-cast, the prise can match the project, knife, environment, or artistic idea. More to come!

Return to TopicsI do not generally accept client's blueprints or designs for knife stands, cases, and blocks. I reserve the right as an artist to creatively apply what is in my idea set for the piece or pieces. So far, I do my very best to match the idea, theme, quality, and style of stands to knives, so that both are commensurate, both follow the same artistic and stylistic idea and execution.

As an artist, ideas of display and accompaniment may come to me while I create the knife, ideas and designs that are not available to the client. If a client has given a price range for me to work in, I'll offer him the best value for his investment I can create, but this is usually the singular limitation I have.

There is an immense potential to learn and grow in this field, and I hope to continue that as long as possible in my life. Knife display and sculpture is a rewarding experience and I hope you have enjoyed these photographs of my work. Thanks for being here!

| Main | Purchase | Tactical | Specific Types | Technical | More |

| Home Page | Where's My Knife, Jay? | Current Tactical Knives for Sale | The Awe of the Blade | Knife Patterns | My Photography |

| Website Overview | Current Knives for Sale | Tactical, Combat Knife Portal | Museum Pieces | Knife Pattern Alphabetic List | Photographic Services |

| My Mission | My Knife Prices | All Tactical, Combat Knives | Investment, Collector's Knives | Copyright and Knives | Photographic Images |

| The Finest Knives and You | How To Order | Counterterrorism Knives | Daggers | Knife Anatomy | |

| Featured Knives: Page One | Purchase Finished Knives | Professional, Military Commemoratives | Swords | Custom Knives | |

| Featured Knives: Page Two | Order Custom Knives | USAF Pararescue Knives | Folding Knives | Modern Knifemaking Technology | My Writing |

| Featured Knives: Page Three | Knife Sales Policy | USAF Pararescue "PJ- Light" | Chef's Knives | Factory vs. Handmade Knives | First Novel |

| Featured Knives: Older/Early | Bank Transfers | 27th Air Force Special Operations | Food Safety, Kitchen, Chef's Knives | Six Distinctions of Fine Knives | Second Novel |

| Email Jay Fisher | Custom Knife Design Fee | Khukris: Combat, Survival, Art | Hunting Knives | Knife Styles | Knife Book |

| Contact, Locate Jay Fisher | Delivery Times | Serrations | Working Knives | Jay's Internet Stats | |

| FAQs | My Shipping Method | Grip Styles, Hand Sizing | Khukris | The 3000th Term | Videos |

| Current, Recent Works, Events | Business of Knifemaking | Concealed Carry and Knives | Skeletonized Knives | Best Knife Information and Learning About Knives | |

| Client's News and Info | Military Knife Care | Serrations | Cities of the Knife | Links | |

| Who Is Jay Fisher? | The Best Combat Locking Sheath | Knife Sheaths | Knife Maker's Marks | ||

| Testimonials, Letters and Emails | Knife Stands and Cases | How to Care for Custom Knives | Site Table of Contents | ||

| Top 22 Reasons to Buy | Tactical Knife Sheath Accessories | Handles, Bolsters, Guards | Knife Making Instruction | ||

| My Knifemaking History | Loops, Plates, Straps | Knife Handles: Gemstone | Larger Monitors and Knife Photos | ||

| What I Do And Don't Do | Belt Loop Extenders-UBLX, EXBLX | Gemstone Alphabetic List | New Materials | ||

| CD ROM Archive | Independent Lamp Accessory-LIMA | Knife Handles: Woods | Knife Shop/Studio, Page 1 | ||

| Publications, Publicity | Universal Main Lamp Holder-HULA | Knife Handles: Horn, Bone, Ivory | Knife Shop/Studio, Page 2 | ||

| My Curriculum Vitae | Sternum Harness | Knife Handles: Manmade Materials | |||

| Funny Letters and Emails, Pg. 1 | Blades and Steels | Sharpeners, Lanyards | Knife Embellishment | ||

| Funny Letters and Emails, Pg. 2 | Blades | Bags, Cases, Duffles, Gear | |||

| Funny Letters and Emails, Pg. 3 | Knife Blade Testing | Modular Sheath Systems | |||

| Funny Letters and Emails, Pg. 4 | 440C: A Love/Hate Affair | PSD Principle Security Detail Sheaths | |||

| Funny Letters and Emails, Pg. 5 | ATS-34: Chrome/Moly Tough | ||||

| Funny Letters and Emails, Pg. 6 | D2: Wear Resistance King | ||||

| The Curious Case of the "Sandia" | O1: Oil Hardened Blued Beauty | ||||

| The Sword, the Veil, the Legend |

Elasticity, Stiffness, Stress, and Strain in Knife Blades |

||||

| Professional Knife Consultant |

Heat Treating and Cryogenic Processing of Knife Blade Steels |