Jay Fisher - Fine Custom Knives

New to the website? Start Here

"Kotori"

Here on the internet, there seems to be some confusion as to what officially constitutes a dagger. On one "official" site, I read that a dagger is defined as a pointed weapon used for stabbing that has no cutting edges! I don't know what world history these guys are looking at for their definitions, but it's not English, and it's not current. A dagger is strictly defined as a short weapon used for stabbing. This says nothing about the cutting edges. The word dagger is only the general definition, other specific types of daggers by historical definition are: athane, athame, poniard, stiletto, dirk, misericord, and anlance. The only commonality these words share are that they are describing a pointed knife used to stab, or a ceremonial tool of specific symmetrical design. Even the term Bowie knife has been used to describe a dagger, but this refers only to symmetrical styles and not to what most modern Americans call a Bowie knife style.

The current and prevalent definition of a dagger is a double-edged knife that is isometric in relationship to its axis. In simple terms, the word dagger refers to knives that have symmetrical double edged blades, and usually have symmetrical handles.

Double edged cutting tools were created in the stone age, so no one knows when the first dagger was made. Perhaps a large spear point from early prehistoric times was adapted for use in the hand. Some of the earliest daggers are made of solid bone, which negates the notion that daggers come only from sword tips that have broken off in battle. Daggers have been created in nearly every culture, and I believe that the basis for the double edged design was based on nature's symmetry, such as the leaf of a plant. The very word "blade" originates in our language from the word blaed, which means the leaf of a plant.

The origins of our English word are Celtic: "dag" (a point). The dagger is probably the most recognizable of all the edged weapons, and though daggers may have been at times used for hunting, survival, and rescue, and they are more universally recognized as stabbing or thrusting weapons, ceremonial objects, and less often working tools.

Hi Jay,

Streamspear arrived today and I am very happy with it! This is a classic as well as a very

classy knife. The class starts even with unwrapping it. The leather sheath itself is beautiful

and in the fabric bag makes you feel like you have something really special in your hands. I

think that only a knife lover can appreciate the true beauty of a knife like this and appreciate

the craftsmanship and skill that has gone into making it. I have to say again the knife is

beautiful! The spear point is a very clean design and all aspects of it are perfectly symmetrical.

The double edge is perfect as well, and is easily the sharpest knife I own. The filework really

gives it the extra class. The balance is excellent and even though it is a longer blade it is

still easy to hold. The dolomite handle is beautiful in itself and adds to the overall appearance

and class to the knife. And when you said it had a mirror polish, you were not kidding!

All in all, a great knife and something that will be the centerpiece of my collection. I will be watching for more knives for sale on your website.

Thank you Jay,

--J.

Though I do make dagger-style combat knives, most of the daggers I make are investment grade works of art. Even knowing that they may never be used, this does not negate the fact that they are made to the highest quality, with modern high alloy tool steel blades, properly hardened and tempered, with durable handles in gemstone, horn, bone, ivory, and exotic woods. A razor-keen double-edged thrusting blade inspires trepidation, and commands immediate attention from those who see those graceful double grinds, particularly when executed in a piece of mirror-finished high chromium stainless tool steel, hardened and tempered, tastefully mounted with full guard, brilliant gemstone handle, and matching intricate pommel. Add a fine sheath or sculptural stand for a stunning display. Truly, today's fine handmade or custom dagger is an investment in a work of art.

It's not easy to make consistent fine daggers. Four symmetrical edges must come to their zenith at once, the spine not neglected, the balance right. I try to make my daggers elegant, graceful, and imposing. To match four independent grinds at once on one piece of steel is a challenge, and I don't use jigs to grind.

You might hear that making a dagger is like making two knives, back to back. This is misleading, because all the grinds in a dagger must match as closely as possible, and be centered along the blade spine. The dagger must be thick enough in the ricasso area of the grind to support the blade length. The handle is usually also symmetrical, as most daggers are designed with symmetry and central axis line balance. The handle must not be too large, as removal of so much blade material in four hollow grinds usually leads to a lightweight blade. Some designs require a small contact wheel for a clean, tight hollow grind that does not sacrifice central spine strength. All my grinding is offhand, and you can read more about that on the blades page here. Most of these are high alloy or high chromium stainless tool steels, and most of them are mirror finished. Some have decorative milling, and all have commensurate and suitable sheaths or stands. The bolsters or guards and pommels are hand-ground and fitted, balanced and detailed. They are owned by collectors, connoisseurs, and tactical specialists and prized for their value, beauty, and fine workmanship.

That's ridiculous. There is no perfect symmetry, particularly in something that's handmade. Clamp a blank of steel in a CNC machining center, and you can get tolerances down to closer than a thousandth of an inch, but don't expect the human hand and eye to have that accuracy. Like every knife that is handmade, it will be imperfect, a testament to the maker's human touch. If you must have complete precision, the solution is to have it made by machine, and then it will have little value. Like embellishment, the nuances of handwork actually enhance the value.

It's not unusual for me to sink several hundred hours into a fine dagger. I'll spread out the work with dozens of other knives, and it may take six months or more to complete a fine dag. It all depends on the amount of work, size, material, and embellishment that goes into the dagger. You can read more about that on my FAQ page here. Often, such elaborate work begs for fine detailing and I'll embellish with detailed filework, etching, or hand-engraving. I even make military and rescue daggers, with mechanisms like locking hookblades, gemstone handles, and full engraving.

Because of the double edge, the dagger is a knife that has to be gripped with care, and is often unsuitable for daily chores. If you have to bear down on the blade, your hand would need to apply pressure at the top of the spine, and in a dagger, another cutting edge is at that location. Also, if you need to cut a container open, you might find that the back cutting edge slices where you don't want it to. When the dagger is used for piercing, you must be ready for the blade to travel either direction, and though it seems a simple thing, you might be surprised at how accustomed we've become to knives that cut in only one direction. Being covered in cutting edges, the dagger blade is somewhat more dangerous than a single edged blade, and it is mostly dangerous to the person holding it. Sheaths, also, must accommodate the double edges, and while pulling or extracting a dagger from a sheath is usually a simple operation, reinserting it may require attention so that the point and edges do not pierce the sheath.

Another concern is that being a dagger, and being small, the hollow grind is usually shallow to preserve spine thickness, so you won't get the longevity of repeated sharpenings of a dagger that you would of a wide single-edged blade with a 10" hollow grind. As the dagger is sharpened (and it will be sharpened if it's used in daily carry), the metal will be worked away, and it can become thick in the grind. I talk about this in detail on my Blades page at this bookmark. Most people who have daggers use them sparingly, or they are for display or fine collections only.

Another concern is a legal one. Most locations in the United States prohibit carrying daggers in public areas. I know this sounds a bit foolish, as a large kitchen knife with an 8" blade could do as much or more harm or injury. These same public places may allow carry of a firearm, as long as it is not concealed. In our state, as in many others, it is up to a jury to determine the character of a knife if it plays a role in a crime, and a dagger's character is traditionally regarded as strictly a weapon. I've heard of beautiful investment grade daggers being "confiscated" by overzealous authorities, never to be seen again! They're probably in private collections now... with other confiscated daggers.

The final concern might be investment value. A beautiful gemstone handled dagger can be a solid, serious investment, but the value of the investment must be preserved. If the knife is used daily, repeatedly sharpened, scratched and dinged, the value of the knife diminishes, sometimes considerably depending on condition. A collector cannot reasonably expect an increase in value if a knife has been used enough to deface it or show serious signs of wear.

Like any fine handmade or custom knife, a dagger's cost and value depends on a variety of factors, and these are outlined on my FAQ page at this bookmark. A dagger is more challenging and expensive than a single edged knife or even a non-symmetrical double-edged knife because of the time and effort to create those balanced grinds. It would not make sense to take the time and effort to make an expertly ground dagger blade in a cheap way. Many daggers have fine and sculpted components, detailed embellishment, and rare handle materials. Sheaths, stands cases, and accoutrements should be commensurate with the quality of the blade, handle, and overall theme. For the beginning range of cost of a fine dagger, please refer to my Knife Prices page here. Please email me for a quote on your next dagger!

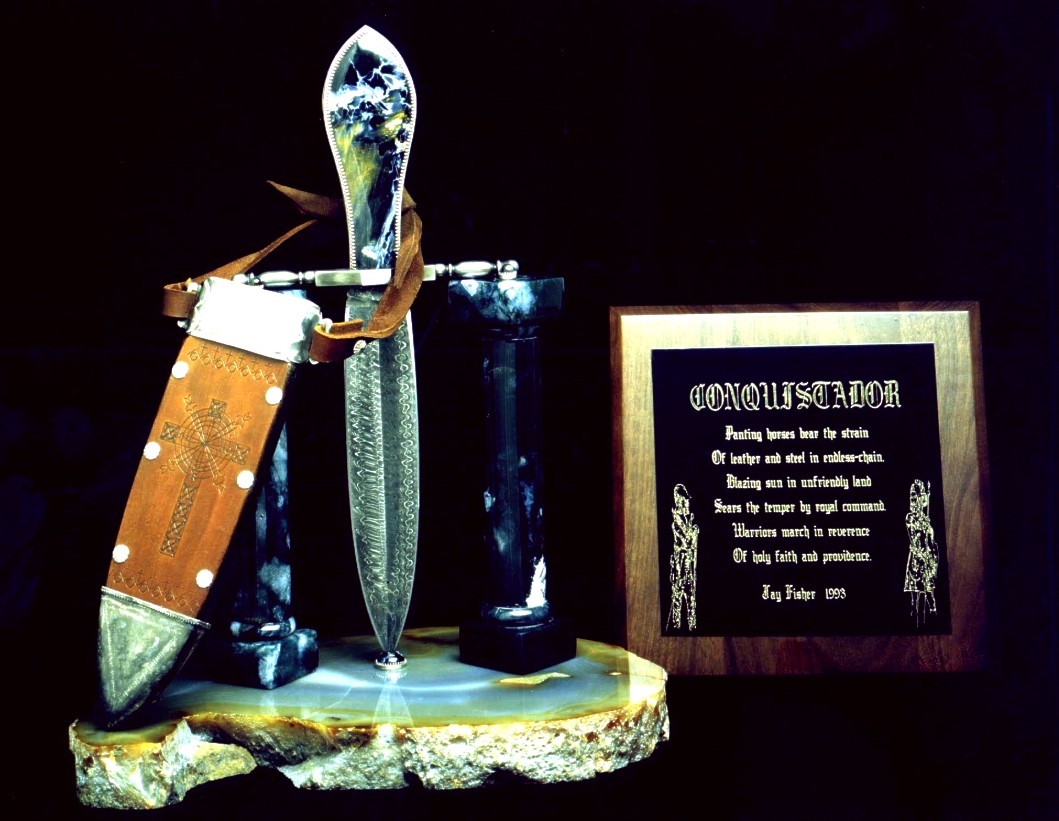

Here's a knife I made many moons ago... back in 1993. Conquistador is a fine art dagger. The theme can be best described by a poem I wrote that accompanies the knife on an engraved black lacquered brass plaque:

Panting horses bear the strain

Of leather and steel in endless-chain.

Blazing sun in unfriendly land

Sears the temper by royal command.

Warriors march in reverence

Of holy faith and providence.

Conquistador has a blade made from low and high carbon steel, pattern welded damascus, hollow ground, etched, and highlight blued. I made the crossguard from mild steel, antiqued to match the finish of the damascus blade. The handle is a breathtaking stormy piece of polished Pietersite Agate gemstone from Africa, wrapped in sterling silver royal cross gallery wire. The accompanying sheath is made of engraved (yes, engraved) leather shoulder, with engraved silver plate chape mouthpiece and chape tailpiece and decorative screws. The knife and sheath rest on a gemstone stand, sculpted from polished Indian green moss agate (pillars), lapped and polished Brazilian agate (base) and Pietersite agate and silver accents. A gorgeous piece reminiscent of time past.

Please click on the links below to go to individual pages of featured daggers.

If you're interested in the price of an authentic, well made, real custom dagger, please check my Knife Prices page and then Email me for a quote.

Featured Dagger Pages:

| Main | Purchase | Tactical | Specific Types | Technical | More |

| Home Page | Where's My Knife, Jay? | Current Tactical Knives for Sale | The Awe of the Blade | Knife Patterns | My Photography |

| Website Overview | Current Knives for Sale | Tactical, Combat Knife Portal | Museum Pieces | Knife Pattern Alphabetic List | Photographic Services |

| My Mission | My Knife Prices | All Tactical, Combat Knives | Investment, Collector's Knives | Copyright and Knives | Photographic Images |

| The Finest Knives and You | How To Order | Counterterrorism Knives | Daggers | Knife Anatomy | |

| Featured Knives: Page One | Purchase Finished Knives | Professional, Military Commemoratives | Swords | Custom Knives | |

| Featured Knives: Page Two | Order Custom Knives | USAF Pararescue Knives | Folding Knives | Modern Knifemaking Technology | My Writing |

| Featured Knives: Page Three | Knife Sales Policy | USAF Pararescue "PJ- Light" | Chef's Knives | Factory vs. Handmade Knives | First Novel |

| Featured Knives: Older/Early | Bank Transfers | 27th Air Force Special Operations | Food Safety, Kitchen, Chef's Knives | Six Distinctions of Fine Knives | Second Novel |

| Email Jay Fisher | Custom Knife Design Fee | Khukris: Combat, Survival, Art | Hunting Knives | Knife Styles | Knife Book |

| Contact, Locate Jay Fisher | Delivery Times | Serrations | Working Knives | Jay's Internet Stats | |

| FAQs | My Shipping Method | Grip Styles, Hand Sizing | Khukris | The 3000th Term | Videos |

| Current, Recent Works, Events | Business of Knifemaking | Concealed Carry and Knives | Skeletonized Knives | Best Knife Information and Learning About Knives | |

| Client's News and Info | Military Knife Care | Serrations | Cities of the Knife | Links | |

| Who Is Jay Fisher? | The Best Combat Locking Sheath | Knife Sheaths | Knife Maker's Marks | ||

| Testimonials, Letters and Emails | Knife Stands and Cases | How to Care for Custom Knives | Site Table of Contents | ||

| Top 22 Reasons to Buy | Tactical Knife Sheath Accessories | Handles, Bolsters, Guards | Knife Making Instruction | ||

| My Knifemaking History | Loops, Plates, Straps | Knife Handles: Gemstone | Larger Monitors and Knife Photos | ||

| What I Do And Don't Do | Belt Loop Extenders-UBLX, EXBLX | Gemstone Alphabetic List | New Materials | ||

| CD ROM Archive | Independent Lamp Accessory-LIMA | Knife Handles: Woods | Knife Shop/Studio, Page 1 | ||

| Publications, Publicity | Universal Main Lamp Holder-HULA | Knife Handles: Horn, Bone, Ivory | Knife Shop/Studio, Page 2 | ||

| My Curriculum Vitae | Sternum Harness | Knife Handles: Manmade Materials | |||

| Funny Letters and Emails, Pg. 1 | Blades and Steels | Sharpeners, Lanyards | Knife Embellishment | ||

| Funny Letters and Emails, Pg. 2 | Blades | Bags, Cases, Duffles, Gear | |||

| Funny Letters and Emails, Pg. 3 | Knife Blade Testing | Modular Sheath Systems | |||

| Funny Letters and Emails, Pg. 4 | 440C: A Love/Hate Affair | PSD Principle Security Detail Sheaths | |||

| Funny Letters and Emails, Pg. 5 | ATS-34: Chrome/Moly Tough | ||||

| Funny Letters and Emails, Pg. 6 | D2: Wear Resistance King | ||||

| The Curious Case of the "Sandia" | O1: Oil Hardened Blued Beauty | ||||

| The Sword, the Veil, the Legend |

Elasticity, Stiffness, Stress, and Strain in Knife Blades |

||||

| Professional Knife Consultant |

Heat Treating and Cryogenic Processing of Knife Blade Steels |