Jay Fisher - Fine Custom Knives

New to the website? Start Here

"Kotori"

Beyond simple tools: fine instruments and professional works of art.

A beautiful and unique pair of made bread knives, suitable for a variety of breads, in the finest premium materials and treatment, with a sculptural block and beautiful base. This pair is built around the theme of bread, the crusty color, the rich golden texture, the reddish warm highlights, the history of grain and comfort that is culturally bread, in every place on God's earth. The gemstone is eternal, the knives are fine instruments, the stand and base is stable, safe, strong, and a unique work of art.

This is, simply, the finest pair of bread knives you will ever see.

440C high chromium hypereutectoid martensitic stainless steel is an absolutely excellent steel for the professional chef. The reason this steel excels is because it's a martensitic stainless steel, forming an incredibly strong microstructure of martensite, the acicular, hard crystalline allotrope of the best tool steels. It also can be treated to form profuse carbides: iron carbide, chromium carbide, molybdenum carbide and multi-element carbides. These small crystalline structures offer incredible wear resistance and high strength along with excellent toughness. When properly heat treated, 440C is the most corrosion-resistant of all of the high alloy martensitic stainless steels, with little to no chance of corrosion, even in acidic and corrosive environments of the kitchen. It does not form these components easily, it takes extremely complicated heat treatment to bring this out. While it can be conventionally heat treated, the difference between a highly sophisticated processing of this steel and conventional processing is night and day in performance and durability

The pair of fine bread knives is absolutely Food Contact Safe. They are made with extremely corrosion resistant materials, and care is simple and easy, with no concern whatever for corrosion. Because of the materials and the proprietary treatment, this means the cutting edge doesn't corrode, and since wear resistance is incredible, little, if any, sharpening will be ever needed. This is a fine set of bread knives suited to the application by design and intent, with the highest quality and longevity possible.

The Sasserides is a popular pattern of mine for bread knives, because the blade is long, elegant, and lean. Since the steel is very tough, and since the grind is hollow, the blade has very little flexing in use. The graceful lines are eclipsed by the tight, continuous "mini-curtain" serrations I've made on the blade, each one meticulously hand-cut and hand-sharpened for the correct geometry. This allows an aggressive cutting of hard, large, crusty loaves, like roundbreads, boules, sourdough pans, braided breads, and challahs. The serration profile slices with little tearing, and the sharpened tip and blade curvature will allow complete cutting through the bottom of the hardened loaf crusts.

The handle shape of the Sasserides is curvaceous and comfortable, with a large thumb rest area at the front bolster to support pressure when cutting. The downward curvature of the handle accommodates the palm of the hand, and the deep finger curves and belly make this one of my most comfortable knife handles. This particular Sasserides has a more narrow, compact blade than is typical of this pattern, leaving little friction when cutting through loaves that have fillings of nuts, fruits, or meats. The heel of the blade allows the forefinger to clear the board for the tightest, largest loaf cuts.

Incidentally, the Sasserides was originally named for a crater arrangement on the moon, a name derived from a Danish astronomer who lived in the 16th century. The serration profile and curves remind me of a line of impact craters within a large, curving hollow.

The knife is, of course, hollow ground, developing a thin yet substantial cutting edge supported by a strong spine. The surface is mirror polished and hygienic, smooth and even and tremendously easy to clean.

The Courgette has a much different character and purpose than the Sasserides. The first thing noticed is the wider blade, and the incredibly thin cutting edge. I made the Courgette with a deep and wide hollow grind, for tremendous longevity, acute cutting edges, and a thin overall quality and begs slicing. This blade is designed for smaller, tough applications, like bagels, soda breads, ryes, and flatbreads. The serrations are much different than the Sasserides, with concave and keen gentle points that move through the toughest loaves and pieces. Another feature is that the point of this blade is flat, wide, and does not have a cutting edge. I did this because I knew that a blade this wide and even would ultimately be used for applying cream cheese butter, or other topping.

The name Courgette is the French word for zucchini. I chose the name for this knife for two reasons. One, the wide, rounded tip of the knife blade shape reminded me of the squash. Two, this knife profile would be well-suited to cutting tomatoes, cucumbers, and, of course, zucchinis! Many knives are like this, and can cover a variety of tasks. Most bagel knives are thus called "bagel-tomato" knives. It makes me want to have one now, a bagel with a slice of fresh vine-ripened tomato, a dash of salt, and some bacon cream cheese on the top... this one knife can handle all that!

The bolsters of both of the knives are made of 304 high nickel, high chromium austenitic stainless steel. This is the same steel used in Food Contact Safe and approved restaurant equipment, a steel tough enough to be used for stainless steel nuts, bolts, and fasteners. This is a high chromium steel that requires no care whatever; it's extremely corrosion-resistant and will not darken or oxidize in any way, ever. I've mounted the bolsters with zero-clearance peened pins; they are permanently bonded to the knife tangs. The bonding is actually stronger than spot welds since the pins penetrate completely through the tang and are swelled in place. The bolsters are sealed with Food Contact Safe sealant, so the knives meet all Food Contact Safety requirements.

The bolsters are rounded, contoured, and polished for comfort, and are dovetailed to lock and bed the handle scales to the fully tapered tangs. I chose to offer a very clean, smooth spine with no filework for the easiest cleaning possible.

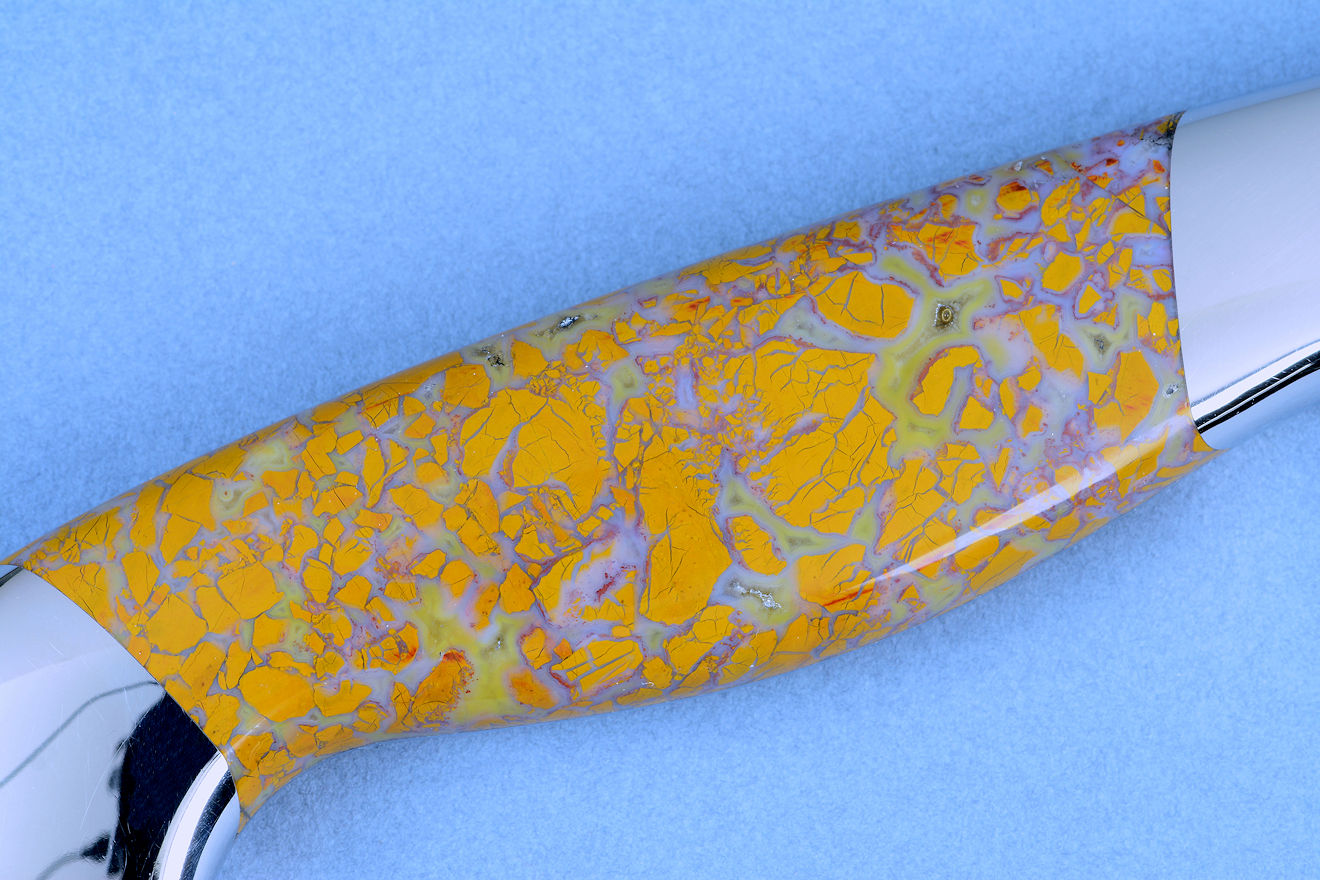

In keeping with the theme and memories of bread: the color, the texture, the feel of warmth, I chose a very distinctive and specific gemstone handle material. This is Stone Canyon Jasper gemstone from the coastal mountains of Monterey County in California. This is a classic lapidary material, used on jewelry and adornment. Seldom does one get to see a large, substantial piece of this magnificent stone, since jewelry is so small overall. More stunning is to pick it up and hold it, cool and dense, and incredibly smooth: it's wonderful to hold.

This is a brecciated jasper, a true jasper of microcrystalline quartz, once broken up into pieces by some geological event, and reformed into a solid, tough, hard, and striking stone over many millions of years. The warm tans remind me of breads, some reddish highlights of singes on crust, all bonded together by a smooth, buttery agate with translucency. You can see into this stone; it has character, it is made by God, perhaps for this very reminder that bread is so critical and important to our lives now and throughout our history.

This jasper is incredibly tough, hard, durable, and solid; an eternal stone that will absolutely outlast all of us. In a million years, it will still look the same, shiny, glassy, smooth and hard, and begging to be gripped.

Man cannot recreate the striking beauty, originality, and unique nature of Jasper. The process takes many millions of years and the coloring comes from impurities in the quartz structure. Jaspers have a higher degree of impurities than agates or chalcedonies, and this is why they are opaque and intensely colorful. Jasper has been adored and used by man for millennia and is mentioned in both the Old and New Testaments of the Bible. This classic material was even identified as the material envisioned for the walls of New Jerusalem.

This everlasting beauty and durability is why I love gemstones, and in this set, they simply sing.

Simply magnificent.

The block for the bread knives had to be complimentary, safe, sturdy, and bold, and it absolutely had to work with the knives. I made this one in American Black Cherry hardwood, commonly called American Cherry, one of our country's most valuable hardwoods. The color of the wood was perfect for the theme, and I built the block around the knives to offer stability and protection, with balance and a great form. Breads are mostly made from wheat grains, so I laser-engraved heavy, full, and bending wheat stalks on the sides of the Cherry, honoring the full harvest that for all of mankind's stay on this earth means so much to be thankful for. How many generations saw stalks heavy with grain and thanked the Almighty for the harvest?

The Granite had to match the project and the theme completely, so I searched for just the right color, tone, and accents. I found it in Kashmir Granite with Garnets, from India. This is a rich, golden granite with hints of reddish highlights, just like the Stone Canyon Jasper, and just like bread, all warm and golden and toasty. This particular granite has Garnets throughout, bits of rich red precious gemstone to accent the thick stone. I cut, carved, and polished the granite, and attached the block so that the piece is extremely stable and solid. Into the bottom of the Kashmir Granite, I inset neoprene feet for a stable, shock-resisting, non-sliding grip on the countertop, allowing air to circulate underneath to keep things dry and hygienic. One of my engraved black lacquered brass legend plates is set into a routed pocket in the base, so that the provenance and materials are always identifiable and clear. It's permanently sealed for longevity and protection against splashes.

This is a pair of bread knives that begs to be used, enjoyed, and cherished by a family in a setting of warmth and comfort. It was an honor for me to make this fine set, and I hope you enjoy the photos as much as I enjoyed making the piece!

| Main | Purchase | Tactical | Specific Types | Technical | More |

| Home Page | Where's My Knife, Jay? | Current Tactical Knives for Sale | The Awe of the Blade | Knife Patterns | My Photography |

| Website Overview | Current Knives for Sale | Tactical, Combat Knife Portal | Museum Pieces | Knife Pattern Alphabetic List | Photographic Services |

| My Mission | My Knife Prices | All Tactical, Combat Knives | Investment, Collector's Knives | Copyright and Knives | Photographic Images |

| The Finest Knives and You | How To Order | Counterterrorism Knives | Daggers | Knife Anatomy | |

| Featured Knives: Page One | Purchase Finished Knives | Professional, Military Commemoratives | Swords | Custom Knives | |

| Featured Knives: Page Two | Order Custom Knives | USAF Pararescue Knives | Folding Knives | Modern Knifemaking Technology | My Writing |

| Featured Knives: Page Three | Knife Sales Policy | USAF Pararescue "PJ- Light" | Chef's Knives | Factory vs. Handmade Knives | First Novel |

| Featured Knives: Older/Early | Bank Transfers | 27th Air Force Special Operations | Food Safety, Kitchen, Chef's Knives | Six Distinctions of Fine Knives | Second Novel |

| Email Jay Fisher | Custom Knife Design Fee | Khukris: Combat, Survival, Art | Hunting Knives | Knife Styles | Knife Book |

| Contact, Locate Jay Fisher | Delivery Times | Serrations | Working Knives | Jay's Internet Stats | |

| FAQs | My Shipping Method | Grip Styles, Hand Sizing | Khukris | The 3000th Term | Videos |

| Current, Recent Works, Events | Business of Knifemaking | Concealed Carry and Knives | Skeletonized Knives | Best Knife Information and Learning About Knives | |

| Client's News and Info | Military Knife Care | Serrations | Cities of the Knife | Links | |

| Who Is Jay Fisher? | The Best Combat Locking Sheath | Knife Sheaths | Knife Maker's Marks | ||

| Testimonials, Letters and Emails | Knife Stands and Cases | How to Care for Custom Knives | Site Table of Contents | ||

| Top 22 Reasons to Buy | Tactical Knife Sheath Accessories | Handles, Bolsters, Guards | Knife Making Instruction | ||

| My Knifemaking History | Loops, Plates, Straps | Knife Handles: Gemstone | Larger Monitors and Knife Photos | ||

| What I Do And Don't Do | Belt Loop Extenders-UBLX, EXBLX | Gemstone Alphabetic List | New Materials | ||

| CD ROM Archive | Independent Lamp Accessory-LIMA | Knife Handles: Woods | Knife Shop/Studio, Page 1 | ||

| Publications, Publicity | Universal Main Lamp Holder-HULA | Knife Handles: Horn, Bone, Ivory | Knife Shop/Studio, Page 2 | ||

| My Curriculum Vitae | Sternum Harness | Knife Handles: Manmade Materials | |||

| Funny Letters and Emails, Pg. 1 | Blades and Steels | Sharpeners, Lanyards | Knife Embellishment | ||

| Funny Letters and Emails, Pg. 2 | Blades | Bags, Cases, Duffles, Gear | |||

| Funny Letters and Emails, Pg. 3 | Knife Blade Testing | Modular Sheath Systems | |||

| Funny Letters and Emails, Pg. 4 | 440C: A Love/Hate Affair | PSD Principle Security Detail Sheaths | |||

| Funny Letters and Emails, Pg. 5 | ATS-34: Chrome/Moly Tough | ||||

| Funny Letters and Emails, Pg. 6 | D2: Wear Resistance King | ||||

| The Curious Case of the "Sandia" | O1: Oil Hardened Blued Beauty | ||||

| The Sword, the Veil, the Legend |

Elasticity, Stiffness, Stress, and Strain in Knife Blades |

||||

| Professional Knife Consultant |

Heat Treating and Cryogenic Processing of Knife Blade Steels |